Innovative plant boosts forest sector, regional economy

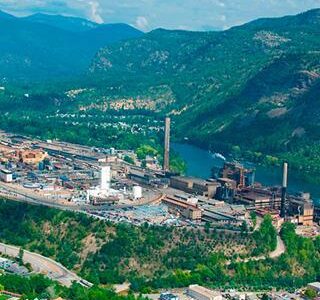

A new state-of-the-art Cross Laminated Timber plant in Okanagan Falls, which officially opened Friday, features innovative technology that will change the way wood is used in B.C., providing another boost to B.C.’s forest industry and regional economic growth.

Structurlam’s new 1,400-square-metre plant expansion was supported by $5.7 million in provincial and federal funding.

The plant takes structural laminated wood products to the next level by producing a new line of CLT, CrossLam, which has been compared in strength to concrete – but is up to six times lighter.

A multi-layer solid timber panel is constructed by bonding dimensional softwood lumber, with each layer at an alternating right angle.

The result is a ready-to-use solid wood building system that offers many advantages to commercial and multifamily construction. These benefits include: faster construction time, greater versatility and stability, and significant environmental benefits.

“In the same way that our glue-laminated beams offer an alternative to steel in long and complex spans, our CrossLam panels provide an alternative to concrete that uses local, renewable resources with compelling structural and environmental advantages,” said Bill Downing, president, Structurlam Products Ltd.

It also uses locally sourced, sustainably managed resources, including western hemlock – which has historically been underutilized – and mountain pine beetle-killed wood.

With wood products currently making up 16 per cent of commercial and institutional construction – compared to roughly 95 per cent in residential construction – there is significant opportunity to expand the use of wood products in B.C.

The plant expansion will create 15 direct jobs in the area, with potential to generate many more as the technology takes hold and there is further growth.

Quick facts

- Using wood can limit climate change due to the reduced energy required to create wood building products and through carbon storage in the wood itself. Every tonne of wood material used in construction saves about 5.7 tonnes of carbon dioxide from being released into the atmosphere.

- Due to alternating grain directions of the lamellae and gluing at high pressure, effects of shrinkage and swelling are minimal and panels are able to transfer load in more than one direction. Panels are pre-fabricated to precise tolerances in a controlled environment, resulting in a stable, uniform and efficient building material.

- CLT construction is a relatively quick and quiet process that takes up less space and generates less site waste. The ability to dramatically accelerate construction schedules with less disruption to neighbours increases feasibility for infill or challenging building sites.

Learn more

- Learn more about Cross Laminated Timber at: http://www.fpinnovations.ca/pdfs/SP52CrossLaminatedTimber_the_boook.pdf

- Wondering how CLT performs in an earthquake? Check out this video that shows the seismic sturdiness of a CLT seven-storey building, during a simulated earthquake that compares to the devastating Kobe earthquake of 1995: http://www.youtube.com/watch?v=T08KRyVhyeo&feature=BFa&list=PL0C748D60E698719A&index=13

- To learn about Structurlam, visit their website: www.structurlam.com